GULFPORT, MS

Night shift produces smooth landings at GPT

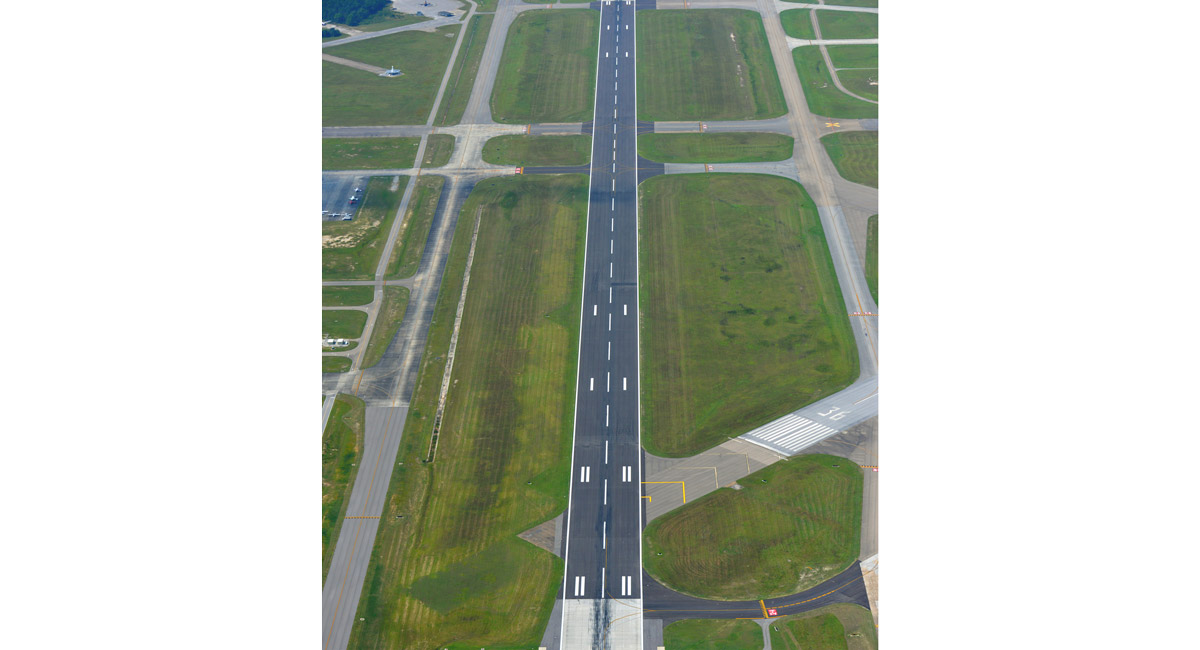

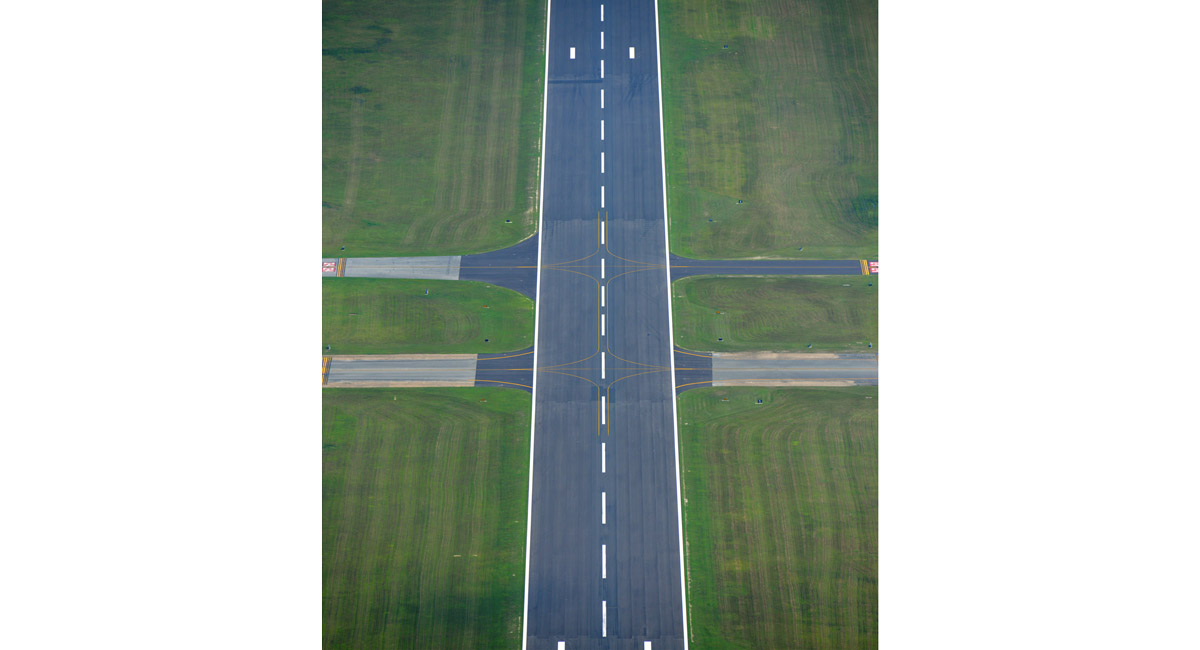

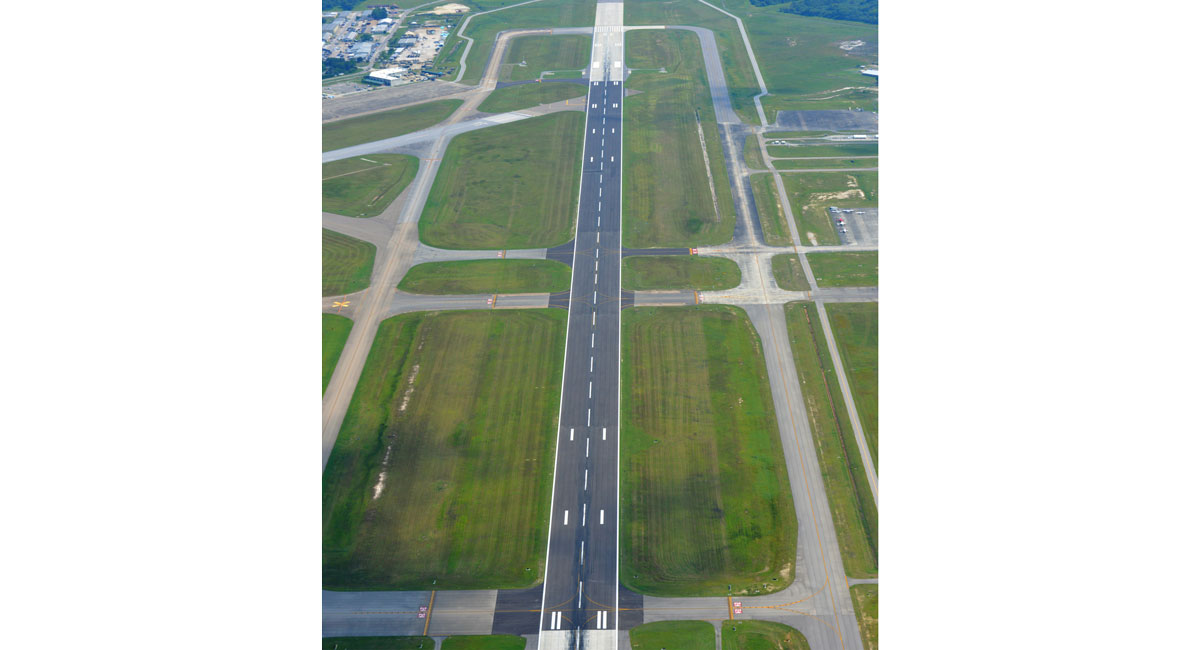

Neel-Schaffer provided a wide variety of services for a $5.9 million project to resurface the 5,500-foot long by 150-foot wide asphalt section of Runway 14-32 at Gulfport-Biloxi International Airport, the main runway at the busiest airport on the Mississippi Gulf Coast.

This was the last piece in a larger puzzle to rehabilitate the 9,002-foot runway after a Pavement Condition Index completed by NS in 2013 identified alligator cracking, block cracking, depressions, longitudinal and transverse cracking, patching, and weathering along the runway. Neel-Schaffer managed the project to replace the concrete touchdown zones on each end of the runway in 2014, and in 2017 the Gulfport-Biloxi Airport Authority took bids to mill and overlay the asphalt portion of 14-32.

Kreg Overstreet, PE (Biloxi), was the project manager and served as the liaison between the client and the contractor, Warren Paving of Gulfport. We also provided engineering design and CE&I for the project. Construction began on April 10, 2017, and was completed on August 18, 2017. All the construction work was completed at night, under a very tight deadline, because one of the requirements of the contract was that the runway would stay open every day – and there would be no flight delays caused by the construction.

“There were no flight delays whatsoever associated with this project,” said Overstreet. “That’s definitely a big deal. That’s their main runway for commercial, industrial, and cargo traffic.”

The project included milling and replacing the asphalt in nightly doses, usually between 10:30 p.m. and 4:30 a.m. “We would shut the runway down soon after the last arriving flight each night,” said Overstreet. “That meant as early as 9 p.m., but sometimes as late as 1:30 in the morning. Sometimes if things were running too late, we’d call that night off and wouldn’t work.”

Overstreet said about 50 construction workers and a variety of trucks, pavers, and milling machines would queue up, then spring into action: “It was like a race.” By 4:30 a.m., the milling and paving would cease, then workers would quickly clear the runway, repaint any striping or markings that had been disturbed, and have the runway ready for the first flights at 6 a.m.

“I can’t stress enough the teamwork that went into this project,” Overstreet added. “We worked really closely with the owner and their operations department to coordinate everything. They were really pleased with how we worked with them. This project has really endeared us to them as far as our client relationship.”